TECHNICAL INFORMATION

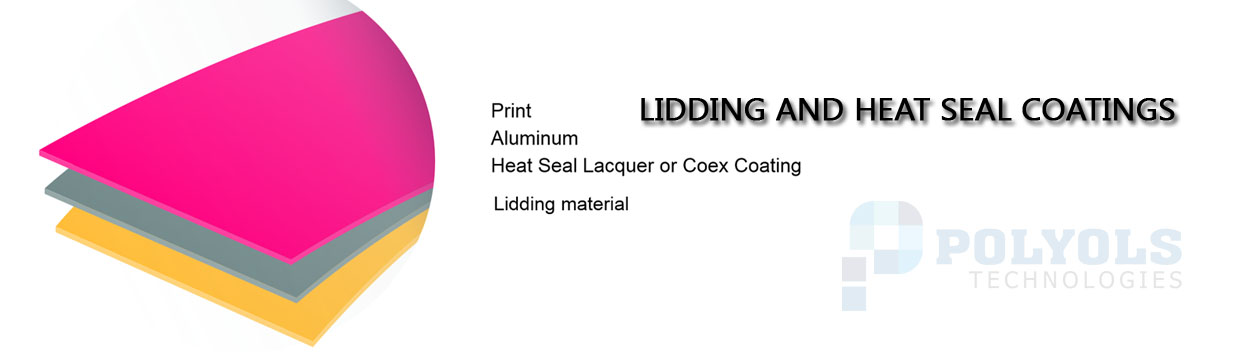

LIDDING AND HEAT SEAL COATINGS

Product |

Resin Type |

Solid content (%) |

Viscosity |

Diluents |

Dry Coating |

Sealing Temperature |

Application |

8226HSC |

EVA |

18% |

19 - 23 SEC (DIN4) |

Aliphatic Hydrocarbons |

3,0 - 4,0 |

60 - 130°C |

Low temperature sealing heat seal which can be applied to various films and sealed to various other films or plastics in a |

8212HSC |

Complex Mixture |

40% |

700 - 900mPas |

Ethyl Acetate MEK |

2,5 - 3,5 |

140 - 220°C |

Lidding heat seal for application to the plain PET side of Paper / PET or Paper / MET PET lidstock. |

122HS |

Vinyl / Acrylic |

38% |

72 - 88 SEC (BSS4) |

Ethyl Acetate MEK |

5,0 - 7,0 |

180 - 220°C |

Peelable universal lidding heat seal for application to aluminium foil, chemically treated or primed polyester film, sealing to PS, APET, PVC, PP, PE. Minimum oven drying temperature is 110°C |

8146HSC |

Polyester |

25% |

23 - 29 SEC (BSS4) |

Ethyl Acetate Acetone |

2,5 - 3,5 |

100 - 200°C |

Heat seal for application to plain polyester film sealable to APET , CPET trays for use primarily in Dual ovenable ready meal |

8228HSC |

Complex Mixture |

38% |

200 - 400mPas |

Ethyl Acetate MEK |

2,5 - 3,5 |

140 - 220°C |

Lidding heat seal for application to the plain polyester faced lidding complexes eg MET PET, Paper/PET or Paper/MET PET, Alufoil/PET. Sealable to PS and used principally for dairy |

8256HSC |

Complex Mixture |

38% |

300-600 mPas |

Ethyl Acetate MEK |

5,0 - 7,0 |

100 - 220°C |

Peelable universal lidding heat seal for application to aluminium foil or polyester sealingto PS, APET, PVC, PP, PE. |

6045HSC |

Epoxy |

31% |

55 - 65 SEC (BSS4) |

MEK |

5,0 - 10,0 |

180 - 220°C |

For use in conjunction with Morprime and NC-6107 as a sterilisable lidding heat seal for aluminium foil, sealing to PP containers or pharmaceutical blister packaging. High temperature |

6213HSC |

Vinyl / Acrylic |

48% |

1500 - 2500mPas |

Ethyl Acetate MEK |

5,0 - 8,0 |

160 - 200°C |

General purpose lidding and pharmaceutical blister heat seal for application to aluminium foil, sealing to PS, PVC, APET. |

In Polyurethane Application Segment, TECHNOL Aliphatic polyester polyols are mainly used in order to improve elastomeric properties in the molecular structure.

read moreAromatic saturated polyetser polyols developed for the manufacturing of Rigid PUR and Polyisocyanurate foams.

read moreTECHNOL FPA GRADE provides excellent adhesion when the application applied to co-extruded or plain biaxially oriented PP/PE film. This can also be over-coated with...

read moreWe are always here to help you with your any doubt our team of experts will get back to you once you raise your comments.